Category

0.5-20 T Coal Fired Steam Boiler Coal Hot Water Boiler for Power Heating Company

Overview Product DescriptionFeatures: 1. Reasonable heat surface and burning device, heat efficiency is 4%~5% higher tha

Basic Info

| Drum Placement | Horizontal Boiler |

| Pressure | High Pressure |

| Manufacturing Level | A |

| Burning Style | Fluidized Bed Furnace |

| Usage | Industrial |

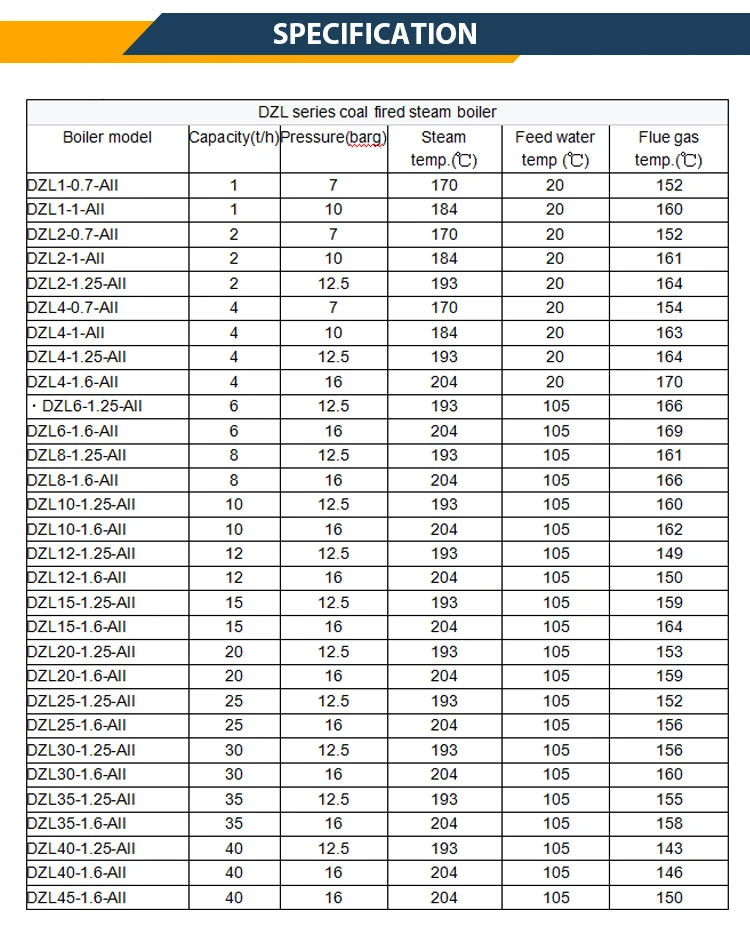

| Steam Production | 1-100 T/H |

| Thermal Efficiency | >81% |

| Output | Steam or Hot Water |

| Weight | Depends on The Capacity of Size |

| Design Fuel | Coal, Biomass, Wood Pellet |

| Steam Capacity | 1-100 T/H |

| Drum | Sing Drum |

| Pass | Three Passes |

| Other Boiler Types | Oil/Gas-Fired Boiler, CFB Boiler, Biomass Boiler |

| Grate | Chain Grate |

| Warranty | 1 Year |

| Video Outgoing-Inspection | Provided |

| Applicable Industries | Hotels, Manufacturing Plant |

| Machinery Test Report | Provided |

| Core Components | PLC, Pressure Parts |

| Transport Package | Standard |

| Specification | Depends on the capacity of boiler |

| Trademark | Taishan |

| Origin | China |

| Production Capacity | 100sets/Month |

Product Description

Features:1. Reasonable heat surface and burning device, heat efficiency is 4%~5% higher than national standard.

2. Reasonable flue gas speed, heating surface without ash deposition and no abrasion, under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

3. The big and tall boiler furnace can be designed according to the different fuel to improve the burning rate of fuel and remove black smoke.

4. All independent loop and reasonable coal boiler injected circulation are specially designed and adopted for the hot water boilers. The medium speed in loop of heat surface is higher than national standard

5. 1-20T/H & 0.7-14MW boiler adopt big and high strength grate, add rolling device improves the boilers' safety, lessen coal leakage and adjust burning conveniently.

6. Over 20T/H & 14MW boiler adopt flake type or beam type chain grate, less coal leakage, convenient burning adjustment. Closed soot cleaning avoid second pollution and save time and labor.

7. Dust inertia separation at the furnace outlet can reduce exhaust gas concentration and lessen abrasion of rear heat surface.

8. Compact structure makes its installation volume smaller than other types of boilers, it will shorten installation period and lower boiler room cost.

9. Big water volume benefits for power-off protection, high ability suitable for load changing.