Water Fire Tube Industrial Coal-Fired Steam Boiler Multi Fuel Fired Coal Steam Boiler

Basic Info

| Function | Steam Boilers |

| Fuel | Coal-Fired |

| Installation | Packaged Boiler |

| Structure | Water Tube |

| Media | Steam and Water |

| Water Circulation | Natural Circulation |

| Drum Placement | Vertical Boiler |

| Pressure | High Pressure |

| Manufacturing Level | A |

| Burning Style | Fluidized Bed Furnace |

| Usage | Industrial |

| Warranty | 1 Year |

| Steam Capacity | Max. 400 T/H |

| Working Pressure | Max. 98 Bar |

| Combustion Method | The Mixture |

| Application | for Power Plant or Industrial Production |

| Machinery Test Report | Provided |

| Core Components | PLC, Pressure Parts |

| Condition | New |

| Output | Steam |

| Weight | Depending on The Boiler Capacity |

| Key Selling Points | High Efficiency |

| Steam Temperature | 170-500 ºC |

| Thermal Efficiency | 85%-90% |

| Grate Type | Step Grate, Chain Grate, Fixed Grate, etc. |

| Fuel Type | Coal, Biomass, etc. |

| Transport Package | Standard |

| Specification | Depending on the boiler capacity |

| Trademark | Taishan |

| Origin | China |

Product Description

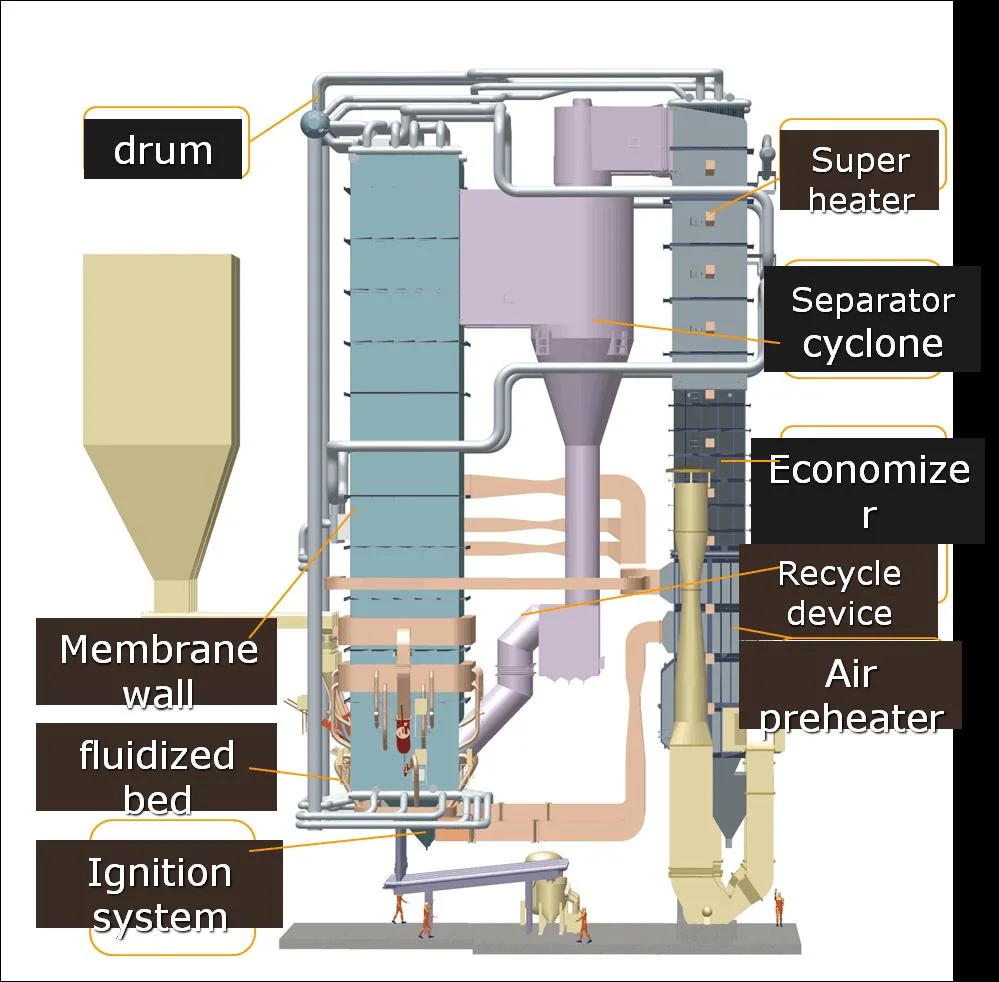

CFB boiler (Circulating Fluidized Bed Boiler) is the kind of widely used coal power plant boiler which features good coal adaptation, safe and reliable operation, high performance and energy saving. The ash may be used as the admixture of cement, decreasing environmental pollution and increasing economic benefit. CFB boiler can burn various fuels, such as soft coal, anthracite coal, lean coal, lignite, gangue, sludge, petroleum coke and biomass (wood chip, bagasse, straw, palm husk, rice husk, etc.)

Our CFB boilers are specially designed and optimized for applications to produce medium and high pressure steam or hot water with rated evaporation capacity from 35 to 440 tons/hr and rated pressure from 3.82 to 9.8 MPa. The CFB boiler design heat efficiency of CFB boilers is up to 87~90%.

Features

1. Burning efficiency reaches 95%-99%, high burning rate, heat efficiency above 87%.

2. Energy-saving, high efficiency, high flexibility of fuel, which can satisfy the burning of many kinds of fuel.

3. Limestone can be added in bed material during burning process reacts with SO2 of flue formulates sulphate, desulphuration can satisfy environment protection.

4. Reasonable wind distribution and low temperature or furnace can control formulation of NOx and really reach environment protection.

5. Big adjusting range load can be adjusted to 30-110%.

6. High automatic control makes boilers running safely and economically in long term.

7. Adopt upper exhaust high temperature cyclone separated device, high collection of bed material.

8. High heat transfer efficiency, high ability of overload.

Application

WNS series gas/oil fired steam boiler is widely used in chemical industry, paper making industry, textile industry, food industry, pharmaceuticals industry, heating industry, construction industry.

Taishan Group has 1.02 million square meters factory with 0.6 billion dollars assets, we have 4,300 employees in 15 wholly-owned and holding subsidiaries, including Taishan Boiler Weihai Shidao Heavy Industry Shandong Luneng Taishan Power Equipment etc. Taian Boao International Trade is the wholly owned subsidiary company of Taishan Group who is responsible for exporting and import business.CertificationsFAQ

1. How to get a boiler price?

Pls tell us below information to confirm the boiler model first, and then offer the right boiler price:

1.1 Which fuel you prefer for the boiler, coal, biomass, gas & oil, or others?

1.2 The boiler capacity

1.3 The boiler pressure

1.4 The boiler application

2. How long is the product warranty period ?

Our boilers have one year warranty period or depending on your requirements.

3. What about after-sale service?

We will supply professional after-sale service team as soon as we receiving your problem feedback, and dispatch our engineers to your country and solve your problems right now.

4. What's the advantages of your company?

4.1 Reasonable heat surface and burning device, heat efficiency is 4%~5% higher than national standard.

4.2 Reasonable flue gas speed, heating surface without ash deposition and no abrasion, under the condition of no soot-blowing, the boiler can work full-load, high-efficiency and safety in long term.

4.3 The big and tall boiler furnace can be designed according to the different fuel to improve the burning rate of fuel and remove black smoke.

4.4 All independent loop and reasonable coal boiler injected circulation are specially designed and adopted for the hot water boilers. The medium speed in loop of heat surface is higher than national standard