Category

Fuel Saving Steam Boiler Gas Fired Boiler Efficiency Rating Hho Hydrogen Gas Boiler for Heating

Fuel Saving Steam Boiler Gas Fired Boiler Efficiency Rating HHO hydrogen gas boiler for heating The Technical Parameter

Basic Info

| Model NO. | OH7500 |

| Drum Placement | Vertical Boiler |

| Pressure | Pressure |

| Manufacturing Level | A |

| Burning Style | Chamber Combustion Boiler |

| Usage | Industrial, Vehicle, Power Station |

| AC Voltage | 380V, 50/60Hz |

| Max Water Consumption | 5L/H |

| Max Gas Output | 7500L/H |

| Water Feed | Auto |

| Features | Energy Saving, Low Carbon Emission, Eco-Friendly |

| Rated Power | 35kw/H |

| Applications | Hho Boiler Heating, Welding, Hho Metal Cutting |

| Output Type | AC Three Phase |

| Gas Source | Gas |

| Certification | CE, ISO9001 |

| Transport Package | Standard Export Wooden Case Packing |

| Specification | 850*1300*1820mm |

| Trademark | OKAY ENERGY |

| Origin | Made in China |

| HS Code | 8405100000 |

| Production Capacity | 200 Sets/Month |

Product Description

Fuel Saving Steam Boiler Gas Fired Boiler Efficiency Rating HHO hydrogen gas boiler for heatingThe Technical Parameter

Larger industrial oxyhydrogen generator

| Model Number | OH1500 | OH3000 | OH5500 | OH7500 | OH10000 | OH20000 |

| AC Voltage Requirement (V) | 380 | 380 | 380 | 380 | 380 | 380 |

| Phase | three | three | three | three | three | three |

| Rated Power(KW/h) | 4.5 | 9 | 17.5 | 23 | 31 | 70 |

| Max Gas Output | 1500L/h | 3000L/h | 5500L/h | 7500L/h | 10000L/h | 20000L/h |

| Max. Working Pressure (kg/cm 2 ) | 2 | 2 | 2 | 2 | 2 | 2 |

| Max. Water Consumption (L/h) | 0.8 | 1.6 | 2.8 | 4 | 5.6 | 11.6 |

| Water Feed | auto | auto | auto | auto | auto | auo |

| Dimensions - L*W*H (mm) | 1070*670*1000 | 700*1100*1280 | 750*1300*1650 | 850*1300*1820 | 1050850*1300*1820*1400*1900 | 2300*1100*1800 |

| Gross Weight (kg) | 210 | 300 | 396 | 552 | 610 | 1400 |

| Ventilation Space Requirement (mm) | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction | 400 in each direction |

Product Description

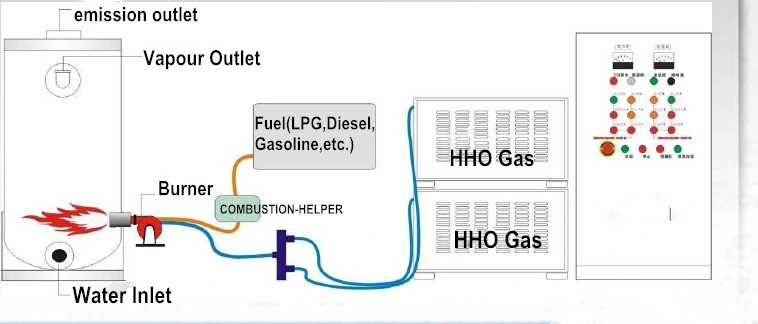

oxy-hydrogen generator combustion-supporting on boilers

HHO Hydrogen Generator for boilers consumes water and electricity, and electrolyze water into hydrogen gas and oxygen gas, we can use H2 and O2 as a source of flame replacing LPG, Propane, Acetylene fuel or natural gas or other oil. Unlike gas and oil, when hydrogen burns it releases no CO2 emissions, merely water vapor. The HHO gas technology for gas/oil/coal-fired boilers is widely applied for home heating, power lighting or other electrical appliances which featured low carbon emission,energy-saving, and easy and safe operation.

How does HHO hydrogen generator work on steam boilers?

I.g Connecting the HHO hydrogen generator's gas out pipe tube to the air and fuel inlet of steam boiler.The mixed oxygen and hydrogen gases feed into the combustion chamber for sufficient burning once the machine power on.

HHO Features and Advantages for boilers

1. Catalysis characteristic

--Hydrogen is an active catalyst which can be mixed with air to feed in to catalyze and

combust all solid, liquid, gas fuel.It also can speed up the reaction process, promote

combustion completely.

2. Energy saving

--HHO gas is generated only using electricity and pure water. The cost of electricity and water can be reduced more than 40% compared with LPG, Propane, and Acetylene fuel.

--Both economical and practical.Energy Saving more than 30% compared with traditional LPG, Propane, and Acetylene fuel.

3. Safety & Easy Operation

--Steady, reliable fuel delivery.Fuel is available immediately after machine is switched on.No need of gas cylinder, which can rupture or explode.

--Multiple safety devices, including overheating and in-sufficient water cut-off switches, will automatically turn off power to ensure the safety of both equipment and user.

4. No pollution & eco-friendly

--The mixed oxygen and hydrogen gas burns completely without creating pollutants, toxic fumes, or public nuisance.

--No harmful hydrocarbons, carbon monoxide, or carbon dioxide.

5. Low Heat Loss

--Use of oxyhydrogen fuel provide a more focused heat source with less heat loss, maintaining a more comfortable, safer, lower fatigue working environment.

Other wide applications

1. Cutting metals by oxyhydrogen flame

2. Gas welding and flame spray painting

3. Thermal processing of jewelry, especially good for platinum as oxy-hydrogen flame contains no carbon

4. Fine cutting, fusion, repair and local thermal processing of delicate metal parts.

5. electric motors copper wire and enameled wire brazing

6. Be applicable to continuous casting templet in the steel factory

7. Removals of carbon deposit in the combustion chamber of internal combustion engine such as cars engine carbon cleaning

8. LED chip integration

9. The thermal processing of glass and quartz glass/ampoule sealing

10. Surface polishing of organic glass/acrylic flame polishing

11. Computer wire peeling

12. Burn with other fuels together for boilers, cooking stoves, melting metals.

Shipment and Package

About shipping, We have long-term cooperated shipping countries providing one-stop safety and quick shipping service.

Flexible Shipping method by international express(DHL, FedEx, UPS, etc), by air, by sea as your requirement. Or using your shipping forwarder.

About Package Standard export package, 1 set/carton;For industrial larger machine, 1 set/wooden pallet;

Okay Service

1.24hour online chat, email or phone support for inquiry, technical and after-sales service;

2.Warranty:1year.(The core part of the machine for 1 year.The other parts of the machine for half of the year in addition to human damage;

3.Online trade assurance service(Protection buyer's payment regarding on-time delivery and product quality.)

Company Introduction

Okay Energy Equipment is one of the largest manufacturers in producing oxyhydrogen generators for over 15 years, we have autorized CE,ISO9001 certificates, and our own patents. We provide the best service and high-quality products to our customers. If you have any questions, pls don't hesitate to contact us.